Prototyping, the vital step of transforming an idea into a tangible model, is undeniably an essential facet of modern product development. With the rise of the digital age, the manufacturing landscape is rapidly shifting, and CNC machining stands out as a game-changer.

Computer numerical control (CNC) machining is an innovative manufacturing process where computers drive machine tools to create detailed and precise parts. According to a recent report, the global CNC machines market size was valued at $86.83 billion in 2022 and is expected to grow further.

Such growth underscores the increasing reliance and importance of CNC technologies, particularly in prototyping, setting the stage for a new era of manufacturing. In this post, we’ll explain how CNC machining has become an integral part of the prototyping process.

CNC Machining: Revolutionizing Prototyping Services

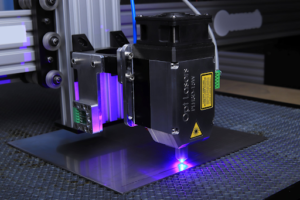

At the heart of CNC machining is its capability to translate a computer-aided design (CAD) file into actionable instructions for machine tools. This process involves a variety of specialized CNC equipment, ranging from mills and lathes machine to routers and grinders. This diversity in machinery, combined with CNC’s intrinsic precision and automation, empowers manufacturers to fabricate detailed and consistent components repeatedly.

In the past, prototyping services predominantly relied on manual techniques. These methods, while functional, were labor-intensive and lacked the precision that modern industries often demand. With the integration of CNC machining into prototyping services, a transformative shift is evident.

Prototypes can now be developed faster, with unparalleled accuracy, and can be swiftly modified as needed. This evolution underscores how CNC machining has not only enhanced the quality and efficiency of prototypes but has reshaped the landscape of prototyping services altogether.

Advantages of CNC Machining in Prototyping

Speed & Efficiency

One of the most notable benefits of CNC machining in prototyping is its speed. Designers can quickly transition from a concept in a digital format to a physical prototype. If design changes are needed, adjustments to the CAD file can be done swiftly, allowing for almost immediate iterations.

Accuracy & Precision

CNC machines boast a high level of detail. Since the operations are computer-controlled, the risk of human error is minimized, which is particularly beneficial when intricate details are essential to the prototype’s functionality.

Material Flexibility

CNC machining isn’t limited to just one or two materials. From metals to plastics and more, a wide variety of materials can be used, allowing the prototype to closely mimic the final product in both look and feel.

Cost-Effectiveness

While there’s an initial investment in CNC machinery and setup, the overall process becomes more cost-effective in the long run. With reduced waste and efficient use of materials, the cost per prototype can decrease, especially when producing short runs or limited series.

Consistency

In prototyping, producing multiple copies that mirror each other perfectly is often a critical requirement. This is especially true for industries where even a minuscule deviation can compromise the entire project’s integrity.

Here, thanks to its computer-controlled precision, CNC machining guarantees that every prototype iteration mirrors its predecessor down to the finest detail. No matter how many times a design is replicated, each version will match the original specifications with unwavering accuracy.

Limitations of CNC Machining in Prototyping

Despite the numerous advantages, there are limitations to CNC machining in the realm of prototyping. Initial setup time can be extensive. Designers must develop detailed CAD models, and machines need specific settings, which can delay the start of actual prototyping. In terms of material limitations, not all materials are ideal for CNC machining. Some, while machinable, might be expensive or not readily available.

Moreover, complexity & size constraints can also pose challenges. There are intricacies that might be beyond a machine’s capability, and there’s also the physical size limit of what a particular CNC machine can produce.

When to Choose CNC Machining Over Other Prototyping Methods

The decision to use CNC machining versus other methods like 3D printing, injection molding, or manual prototyping hinges on various factors. Consider the project’s scale, required materials, precision needs, and desired timeline. For instance, while 3D printing might be quicker for a single complex prototype, CNC might be preferable for multiple copies that need consistent and precise replication.

Future Trends: CNC Machining and Prototyping

The trajectory of CNC machining in prototyping seems promising. Continuous advancements in CNC technology are evident in the ever-evolving software, innovative materials, and enhanced machine capabilities. As the lines between various manufacturing technologies blur, the convergence of CNC machining with other techniques will likely lead to even more versatile prototyping solutions.

Final Thoughts

In essence, CNC machining has undeniably cemented its role in modern prototyping. Its capabilities have ushered in an era where prototypes are faster, more accurate, and more reflective of the final product than ever before. For businesses seeking to remain competitive, investing in or considering CNC machining for prototyping is not just advisable; it’s almost imperative.