Trailer landing gear play a crucial role in the stability and safety of semi-trailers during loading and unloading operations. They help support the trailer and prevent it from tipping over when it is uncoupled from the tractor unit, ensuring that the cargo is secure and the trailer remains stable. This article explores the different types of semi-trailer legs, with a particular focus on trailer landing gear and trailer landing legs, as well as the manufacturers behind these essential components.

Types of Semi-Trailer Outriggers

Pull-Out Outriggers

Pull-out outriggers are designed to slide out from the side of the trailer when needed. These outriggers provide substantial support without requiring an outrigger board, making them ideal for scenarios where space is limited. When not in use, these outriggers can be retracted, ensuring they don’t take up unnecessary space during transport. Pull-out outriggers are commonly used in flatbed trailers or lowbed trailers to support heavy loads during operations.

Swing-Out Outriggers

Swing-out outriggers are extendable supports that can swing out from the trailer to provide stability, often with the use of a support board. These outriggers can be easily pushed back when not required, making them a more flexible option for semi-trailers that need to adjust their dimensions depending on the load. Swing-out outriggers are typically used in trailers transporting wide or oversized loads.

Attached Outriggers

Attached outriggers are integrated directly into the trailer structure, providing a robust and permanent solution for stability. They are particularly useful in heavy hauling, where the added support increases the trailer’s width to accommodate oversized or heavy equipment. These outriggers are designed for industries that require high durability and constant use, such as construction and mining.

Intelligent Electric Outriggers

Definition

With the advancements in automation, intelligent electric outriggers are becoming increasingly popular. These systems use sensors and control algorithms to automatically adjust the trailer landing legs for optimal stability. Electric outriggers are equipped with power supplies, sensors, and control units that enable automated control, reducing the need for manual intervention during loading and unloading.

Components

- Electric Outriggers: These are the primary components, providing easy extension and retraction based on load requirements.

- Control Units: These units manage the operation of the outriggers based on real-time data.

- Sensors: Sensors detect the load and trailer positioning, adjusting the outriggers accordingly.

- Power Supplies: These provide the necessary energy for the system to operate.

Benefits

- Enhanced Safety: Intelligent electric outriggers ensure that the trailer remains stable during loading and unloading, reducing the risk of accidents.

- Improved Load Handling: The system’s ability to adjust to different load conditions enhances the efficiency of transporting heavy or delicate cargo.

- Operational Efficiency: Automation reduces the time spent manually adjusting outriggers, streamlining operations and improving overall productivity.

- Trailer Landing Gear and Its Role

Definition

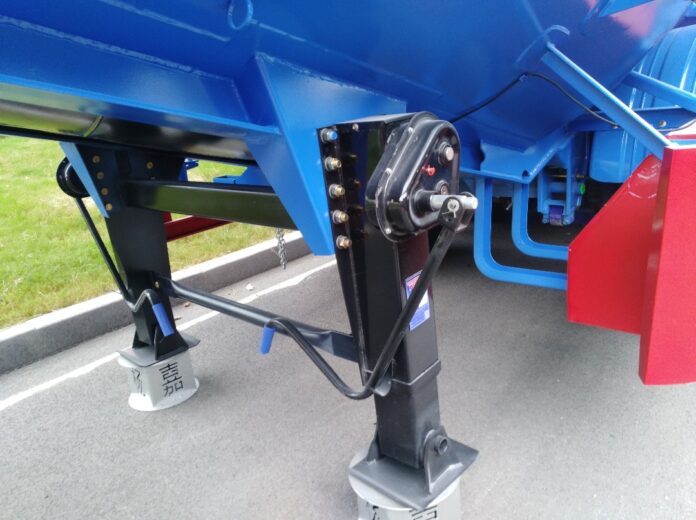

Trailer landing gear is a mechanical system located at the front of a semi-trailer. When uncoupled from the tractor unit, the landing gear supports the entire weight of the trailer, preventing it from tipping or collapsing. This crucial component provides stability during loading, unloading, and storage.

Functionality

Landing gear supports the trailer’s weight and ensures that it remains level while uncoupled. It features adjustable legs that can be extended or retracted to adapt to different ground conditions. The landing gear is essential for keeping the trailer stable, especially when the tractor is detached for unloading or waiting.

Types of Landing Gear

Various types of trailer landing legs are available, with designs tailored to different needs:

- Manual Landing Gear: Operated by a hand crank, this is a more traditional and cost-effective option.

- Hydraulic Landing Gear: Features hydraulic systems for quicker and easier operation, making it ideal for high-frequency use.

- Electric Landing Gear: Powered by electricity, these systems offer a more efficient and less labor-intensive option for users.

Notable Manufacturers

Companies like JOST International offer a wide range of landing gear solutions, providing robust and reliable products suitable for various types of trailers. Their landing gear systems are designed for long-lasting performance, even in the most demanding conditions. Other manufacturers like Fleet Engineers are also known for producing high-quality trailer landing gear that enhances trailer stability and efficiency.

Trailer Landing Gear Manufacturers

The market for trailer landing gear systems is competitive, with several manufacturers providing innovative solutions:

- JOST International: A global leader in trailer landing gear systems, JOST offers a range of manual, hydraulic, and electric landing gear products. Their products are designed to meet the needs of the logistics and transportation industry, providing reliable and durable support for semi-trailers.

- Fleet Engineers: Known for their focus on durability and ease of use, Fleet Engineers produces a variety of landing gear options, from lightweight to heavy-duty models. Their products are designed for maximum stability and longevity, ensuring smooth operations for their clients.

Innovations

Manufacturers like LUEN are also advancing the development of trailer landing gear, offering cutting-edge designs that improve functionality and safety. New technologies in landing gear systems are focused on reducing weight while increasing strength, as well as enhancing ease of use through automation.

Conclusion

In conclusion, trailer landing gear and outriggers are indispensable components for maintaining the stability of semi-trailers, especially during loading and unloading operations. The choice between different types of outriggers—such as pull-out, swing-out, or attached—and landing gear systems depends on the specific needs of the transport operation. Trailer landing legs are critical for ensuring the trailer’s stability when uncoupled, with a variety of options available from manufacturers like JOST International and LUEN. Depending on the load size, frequency of use, and ground conditions, selecting the right system will enhance safety, efficiency, and operational productivity.

For businesses looking for the best trailer landing gear solutions, contacting a trusted trailer landing gear manufacturer such as LUEN can provide access to high-quality, durable, and customizable systems tailored to meet specific transportation requirements.