Unlock the potential of cost-effective CNC turning with our comprehensive guide designed specifically for small businesses. Dive into essential strategies and practical tips that promise efficiency, precision, and a competitive edge in the dynamic world of small-scale manufacturing. Streamline your production processes and elevate your market position with this insightful exploration.

Importance of CNC Turning

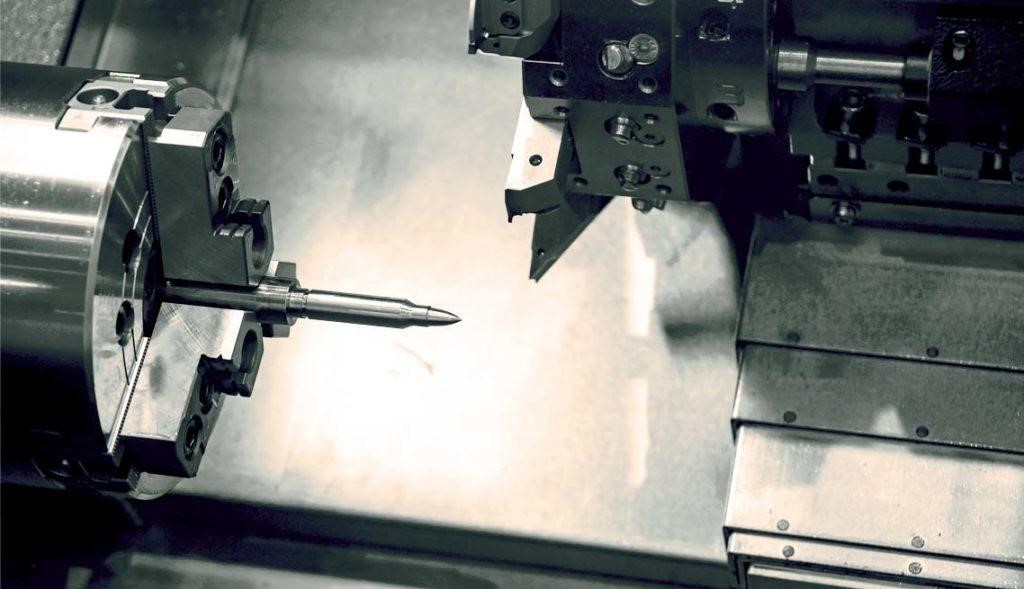

CNC turning, also known as computer numerical control turning, is a subtractive manufacturing process that employs computer-controlled tools to precisely remove material from a rotating workpiece. This highly versatile and automated machining technique is widely used in the manufacturing industry to produce a wide range of precision components, ranging from simple shafts and bushings to complex prototypes and intricate medical implants.

CNC turning plays a crucial role in the manufacturing landscape due to its ability to produce high-quality parts with exceptional accuracy and repeatability. The process offers numerous advantages over traditional manual turning methods, including:

- Greater precision and consistency: CNC machines can achieve tolerances of less than a micron, ensuring consistent part dimensions and eliminating the human error associated with manual machining.

- Improved efficiency and productivity: CNC turning is an automated process, allowing for continuous operation without constant human intervention. This automation leads to faster production times and increased output.

- Reduced labor costs: Automation in CNC turning reduces the need for skilled labor, lowering labor costs and improving overall manufacturing efficiency.

- Enhanced versatility: CNC turning can handle a wide range of materials, including metals, plastics, and composites, making it suitable for a diverse range of applications.

ALT Text: CNC Turning Machine

Significance for Small Businesses

For small businesses operating in the manufacturing sector, CNC turning offers a multitude of benefits that can significantly enhance their competitiveness and productivity. By adopting cost-effective CNC turning strategies, small businesses can:

- Reduce production costs: Automation and precision in CNC turning lead to reduced material waste, lower labor costs, and faster production times, ultimately contributing to lower overall production costs.

- Improve product quality: The high precision and consistency of CNC turning ensure that products meet the highest quality standards, enhancing customer satisfaction and brand reputation.

- Gain a competitive edge: By leveraging the efficiency and versatility of CNC turning, small businesses can respond quickly to customer demands, produce innovative products, and gain a competitive advantage in the market.

- Expand market reach: The ability to produce high-quality precision parts with CNC turning enables small businesses to expand their product offerings and reach new markets.

Fundamentals of CNC Turning

Discover the basics of CNC turning—learn how the machines work, understand the important parts, and see how it’s used in simple terms for effective manufacturing.

Explanation of CNC Turning Process

The CNC turning process involves a series of precisely controlled steps that transform a raw workpiece into a finished product. The process typically involves the following stages:

- Workpiece preparation: The workpiece is secured in a chuck or collet, ensuring it is properly aligned and centered.

- Tool selection: The appropriate cutting tool is selected based on the material, dimensions, and desired surface finish of the workpiece.

- Program creation: A computer-aided manufacturing (CAM) program is used to generate a detailed set of instructions, known as G-code, that defines the toolpath and machining parameters.

- Machine execution: The G-code is loaded into the CNC machine’s control unit, and the machining process commences. The machine automatically controls the movement of the cutting tool, ensuring precise removal of material according to the programmed instructions.

- Part finishing: Once the machining process is complete, the finished part is removed from the machine and may undergo additional finishing operations, such as polishing or deburring.

Key Components and Machinery Overview

CNC turning machines consist of several key components that work together to achieve precise machining:

- Control unit: The control unit, also known as the CNC controller, is the brain of the machine. It interprets the G-code instructions and translates them into commands for the machine’s motors and actuators.

- Spindle: The spindle is the rotating shaft that holds the workpiece. It is driven by a powerful motor and rotates at high speeds to facilitate the machining process.

- Turret: The turret is a rotating tool holder that houses multiple cutting tools. It can automatically change tools during the machining process, eliminating the need for manual tool changes.

- Tool holder: The tool holder securely grips the cutting tool, ensuring it remains firmly in place during machining.

- Cutting tools: Cutting tools come in various shapes and sizes, each designed for specific materials and machining operations. Common types include turning tools, facing tools, threading tools, and boring bars.

Applications in Small Business Settings

CNC turning finds widespread application in various industries, particularly for small businesses, due to its versatility and cost-effectiveness. Some common applications include:

- Production of mechanical components: CNC turning is widely used to produce precision mechanical components, such as shafts, bushings, gears, and spools.

- Prototyping and product development: CNC turning enables rapid prototyping of new product designs, allowing for quick iterations and design refinements.

- Manufacturing of medical devices: CNC turning is employed in the production of intricate medical implants and surgical tools.

ALT Text: CNC Precision Cutting.

Benefits of Cost-Effective CNC Turning

Cost-effective CNC turning brings savings and precision, providing a competitive edge for small businesses. Streamlined processes offer efficiency, making it a strategic investment for improved manufacturing outcomes.

CNC turning offers a range of benefits that can significantly impact the cost-effectiveness and competitiveness of small businesses:

Reduced Production Costs

Reduce production costs through CNC turning, optimizing resources and gaining a competitive edge for small businesses.

- Material savings: CNC turning’s precision and efficiency minimize material waste, reducing overall material costs.

- Labor cost optimization: Automation reduces the need for skilled labor, lowering labor costs and improving overall manufacturing efficiency.

- Reduced tooling costs: Proper tool selection and maintenance strategies extend tool life, minimizing tooling replacement costs.

Improved Efficiency and Precision

Boost efficiency and precision with CNC turning, ensuring top-notch quality for small businesses in a competitive market.

- Faster production times: Automation and continuous operation lead to faster production cycles and increased output.

- Enhanced precision and consistency: CNC turning achieves tolerances of less than a micron, ensuring consistent part dimensions and reducing the need for rework.

- Reduced scrap rates: Precision and consistency minimize the production of defective parts, reducing scrap rates and associated costs.

Competitive Advantages in the Market

- Improved product quality: Consistent high-quality products enhance customer satisfaction and brand reputation.

- Enhanced responsiveness: Rapid prototyping and production capabilities allow for quick adaptation to market demands.

- Diversified product offerings: CNC turning’s versatility enables production of a wider range of products, expanding market reach.

- Reduced time-to-market: Faster production times bring new products to market sooner, gaining a competitive edge.

Tips for Small Businesses

Navigate the world of CNC turning with expert guidance through practical tips tailored for small businesses. From selecting the right machinery to optimizing tooling strategies, these insights empower enterprises to maximize efficiency, reduce costs, and thrive in the competitive manufacturing arena.

Selecting the Right CNC Turning Machine

- Consider workpiece size and material: Choose a machine with a chuck capacity and spindle power suitable for the size and type of materials you will be machining.

- Assess speed and precision requirements: Evaluate the required machining speed and precision to ensure the machine’s capabilities align with your production needs.

- Consider budget and future growth: Select a machine that fits your current budget while accommodating potential future production growth.

Implementing Efficient Tooling Strategies

- Tool selection based on material: Choose cutting tools specifically designed for the material being machined to optimize performance and tool life.

- Strategies for managing tool life: Implement tool rotation schedules and proper tool maintenance practices to extend tool life and minimize replacement costs.

- Consider tool coatings: Utilize tool coatings, such as titanium nitride or diamond-like carbon, to enhance tool wear resistance and increase machining efficiency.

ALT Text: Small Scale CNC Machine

Cost Management in CNC Turning

Manage costs in CNC turning by controlling energy use, reducing material expenses, and adopting smart maintenance practices. This approach ensures small businesses optimize resources for long-term savings and competitiveness in the CNC turning landscape.

Monitoring and Controlling Energy Consumption

- Implement energy-efficient lighting and ventilation systems.

- Optimize machine usage to avoid unnecessary power consumption.

- Utilize variable speed drives to adjust motor speed based on machining requirements.

Strategies for Material Cost Reduction

- Negotiate bulk material purchases with suppliers to secure better pricing.

- Minimize material waste through efficient nesting and cutting techniques.

- Consider using recycled or reclaimed materials when feasible.

Maintenance Practices for Long-Term Cost Savings

- Implement preventive maintenance schedules to identify and address potential issues before they cause breakdowns.

- Regularly clean and lubricate machine components to ensure optimal performance and extend machine life.

- Properly store tools and accessories to prevent damage and extend their lifespan.

Case Studies

Dive into real-world success stories with case studies on cost-effective CNC turning. Discover how small businesses have implemented strategies, overcome challenges, and achieved remarkable results, providing valuable insights for others navigating the CNC turning landscape.

A. Success Stories of Small Businesses Implementing Cost-Effective CNC Turning

- A small machine shop in the Midwest adopted CNC turning and reduced production costs by 20% while increasing output by 30%.

- A dental implant manufacturer implemented CNC turning to produce high-precision implants with improved surface finish, reducing scrap rates by 40%.

- A custom parts manufacturer leveraged CNC turning to expand their product offerings and enter new markets, achieving a 25% increase in annual revenue.

Lessons Learned and Best Practices

- Investing in the right CNC turning machine can significantly impact production efficiency and cost savings.

- Adopting efficient tooling strategies and implementing proper maintenance practices can extend tool life and reduce overall machining costs.

- Continuous monitoring and optimization of energy consumption can contribute to lower operating expenses.

- Collaboration with suppliers and strategic material procurement can minimize material costs and waste.

Future Trends in Cost-Effective CNC Turning

Explore the future of cost-effective CNC turning with upcoming trends. Automation advancements, innovative tooling technologies, and a focus on sustainable practices are shaping the industry, promising increased efficiency and competitive advantages for small businesses in the manufacturing landscape.

Integration of Automation

Revolutionize CNC turning with automation, enhancing efficiency and precision. By seamlessly integrating automated processes, businesses can boost productivity, reduce errors, and stay at the forefront of cutting-edge manufacturing technology.

- Automated tool loading and unloading systems will further reduce labor costs and improve production efficiency.

- Automated part handling systems will streamline the production process, reducing the need for manual intervention.

- Integrated sensors and monitoring systems will provide real-time data on machine performance, enabling predictive maintenance and proactive interventions.

Sustainable Practices in CNC Turning

Embrace sustainability in CNC turning by adopting eco-friendly practices. From energy-efficient operations to responsible material choices, incorporating sustainable measures ensures a greener manufacturing process, reducing environmental impact and fostering a more responsible approach to production.

- Increased adoption of energy-efficient machining processes and renewable energy sources will reduce the environmental impact of CNC turning.

- Utilization of eco-friendly cutting fluids and lubricants will minimize the use of hazardous chemicals.

- Recycling and reuse of machined materials will promote sustainable manufacturing practices.

ALT Text: ECO-Friendly CNC Machine

Conclusion

CNC turning is like a superhero for small businesses, helping them become more productive and competitive in making things. By using smart and affordable strategies, small businesses can make the most out of CNC turning. It’s like a magic wand that makes production smoother, reduces waste, and ensures that the things they make are super good quality for their customers.

Imagine it as a special tool that helps small businesses not just keep up with the big players but even outshine them. With CNC turning, small businesses can tackle challenges in the world of making things, showing everyone that they’re smart, efficient, and ready for whatever the manufacturing world throws at them.